Electroplating

Definition

Electroplating is a process of coating a metal onto another metal surface by hydrolysis, mostly for decorative purposes or to prevent corrosion of a metal. The process uses an electric current to reduce dissolved metal cations to develop a thin, coherent metal coating on the electrode. It is also known as electrochemical deposition or electrodeposition.

Principle of Electroplating

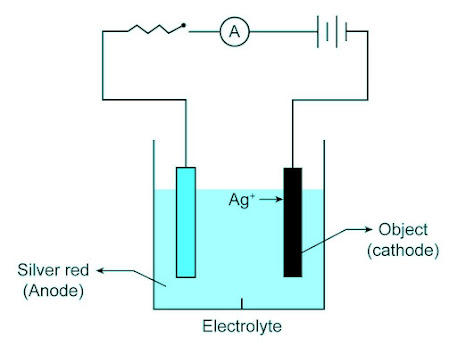

Electroplating involves passing an electric current through an electrolyte, which contains metal ions. The metal ions are reduced at the cathode, forming a thin, coherent layer of metal on the surface of the substrate. The anode, which is made of the same metal that is to be deposited, dissolves into the electrolyte, replacing the metal ions that are being reduced at the cathode.

Working Method

The working method of electroplating involves several steps. Firstly, the substrate to be plated is cleaned and then placed into the electrolyte. An electric current is passed through the electrolyte, causing the metal ions to be attracted to and reduced at the substrate surface, forming a thin, coherent layer of metal. The plating thickness can be controlled by varying the time and current density used during the process.

Benefits of Electroplating

Electroplating offers several benefits, including:

⇒ Corrosion Protection: Electroplating is used to prevent corrosion of metals such as iron, steel, and copper.

⇒ Enhanced Appearance: Electroplating can enhance the appearance of objects by giving them a shiny or reflective surface.

⇒ Improved Durability: Electroplated objects can have improved durability and wear resistance due to the added layer of metal.

⇒ Versatility: Electroplating can be used on a variety of materials such as plastic, wood, and metal.

Uses of Electroplating

Some common uses of electroplating include:

⇒ Jewelry and Decorative Items: Electroplating is often used to coat jewelry and decorative items with gold, silver, or other metals.

⇒ Automotive Industry: Electroplating is used to coat car parts to prevent corrosion and enhance their appearance.

⇒ Electronics Industry: Electroplating is used in the production of electronic components such as printed circuit boards and connectors.

⇒ Aerospace Industry: Electroplating is used to coat airplane parts to prevent corrosion and enhance their durability.

In conclusion, electroplating is a process of coating a metal onto another metal surface using an electric current. It offers several benefits such as corrosion protection, enhanced appearance, improved durability, and versatility. Electroplating is commonly used in jewelry and decorative items, the automotive industry, electronics industry, and aerospace industry.

Frequently Asked Questions – FAQs

⇒ What is electroplating?

Electroplating is the process of plating one metal onto another by hydrolysis, most commonly for decorative purposes or to prevent corrosion of a metal.

⇒ What is the purpose of electroplating?

Electroplating is used to modify the surface properties of an object, such as corrosion resistance, lubricity, and abrasion resistance. It can also be used to add thickness or create objects.

⇒ How is electroplating done?

Electroplating involves immersing a part to be plated (cathode) in a solution containing ions of the metal to be deposited. A current is passed through the solution, causing the metal ions to be reduced and deposited onto the cathode.

⇒ What metals can be used for electroplating?

Metals like copper, tin, gold, silver, nickel, and zinc are commonly used for electroplating.

⇒ What is the thickness of a typical plated metal?

The typical thickness of plated metal varies from about 0.5 microns up to about 20 microns.

⇒ What are some objects that can be electroplated?

Various objects like car parts, wheel rims, bath taps, etc. can be electroplated with metals like chromium, silver, or gold. Jewelers also use electroplating to coat less costly metals with silver or gold .

⇒ What is the difference between electroplating and electroless plating?

Electroplating involves passing a current through a solution to deposit metal ions onto a surface, while electroless plating uses a chemical reaction to deposit a metal layer on a surface without the need for an electrical current.

⇒ What is cyanide electroplating?

Cyanide electroplating is a method of plating metals like silver, gold, copper, and brass using cyanide solutions to give adherent deposits of copper directly on iron and steel.

⇒ What are some benefits of electroplating?

Electroplating can improve the surface properties of an object, such as increasing its durability and resistance to corrosion, wear, and abrasion. It can also enhance the appearance of an object, providing a shiny or matte finish.

⇒ What are some safety concerns associated with electroplating?

Electroplating involves the use of toxic chemicals and heavy metals, which can pose health and safety risks to workers and the environment. Proper ventilation and protective equipment are necessary to minimize exposure to these hazards.

Let me know if you have more questions or if there is a specific topic that you would like to know more about.

If you have any doubts, please let me know